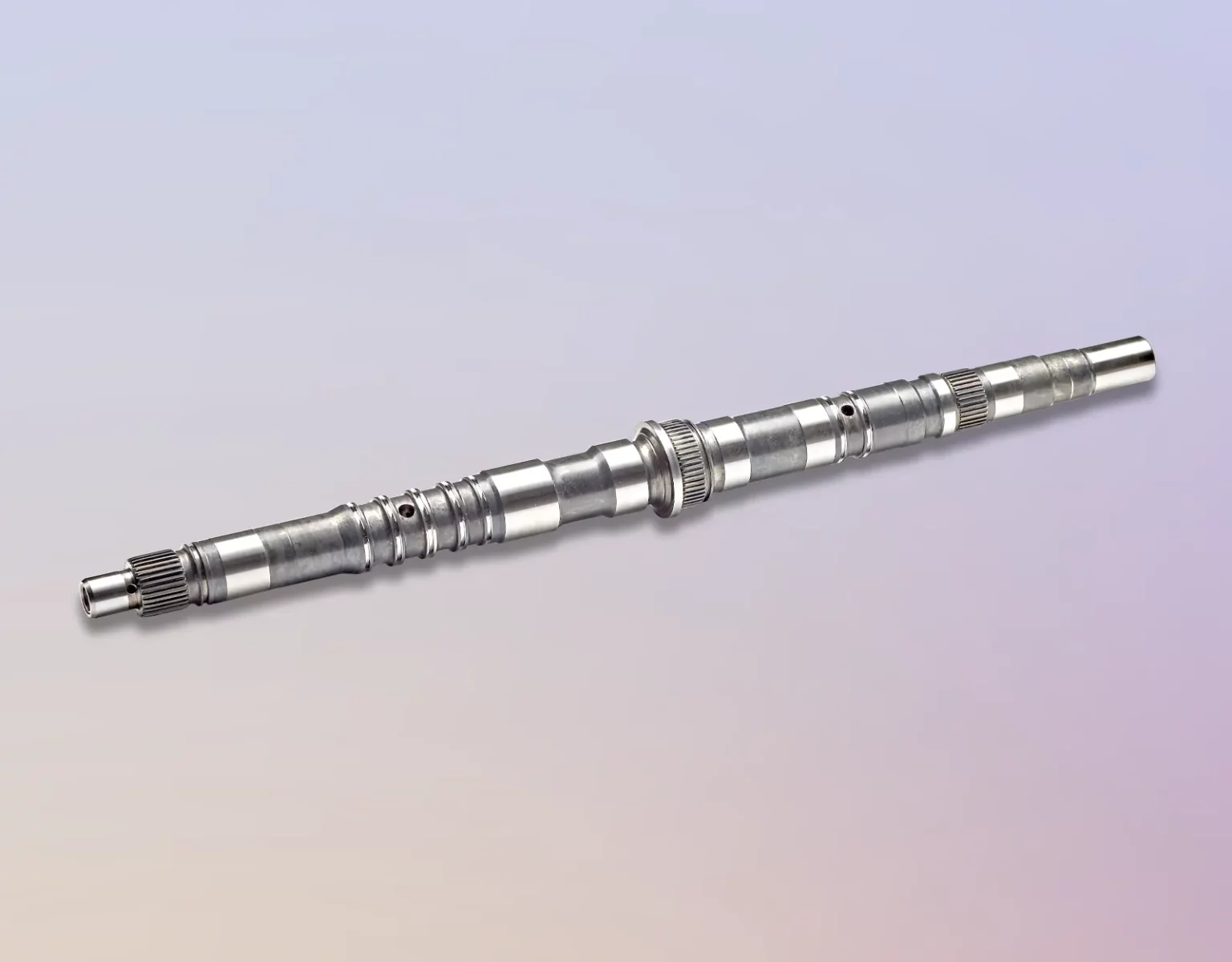

We produce a wide range of key components, including planetary carriers, ring gears, helical gears, and transmission shafts. These parts are essential to the performance of automatic and electrified drivetrains, ensuring smooth power delivery, low vibration levels, and enhanced driving comfort.

Thanks to strong vertical integration and advanced production capabilities, we manage every stage in-house—from raw material transformation to final finishing. This control ensures consistent quality, optimized lead times, and full traceability.

Our machining capabilities include:

- Turning and deep-hole drilling for accurate shaping

- Gear hobbing and gear cutting for precise tooth profiles

- Internal and external broaching to achieve tight tolerances

We apply advanced heat-treatment processes such as:

- Carburizing and direct quenching

- Induction hardening

- Shot-peening

- Tempering

These treatments significantly improve wear resistance, hardness, and component lifespan, making our gears and shafts suitable for demanding environments.

Our final operations include:

- Grinding of internal/external diameters and gear teeth

- Hard-turning for dimensional precision

- Straightening to ensure perfect alignment

In addition, we offer laser and E-beam welding, which contribute to structural integrity and long-term durability under high mechanical stress.

Dumarey’s gears and shafts are engineered to meet strict industry standards while supporting the ongoing transition to more sustainable and electrified mobility.